Premium Vinyl Pressing in the UK

Short Runs From 100 Available

Eco-mix Now 99p Per Disc

A Personal Service On All Your Orders

Speak to the factory direct and get automated email updates at each stage of your order

10-14 Week Lead Time Promise

Lead time dependent on nature of vinyl run

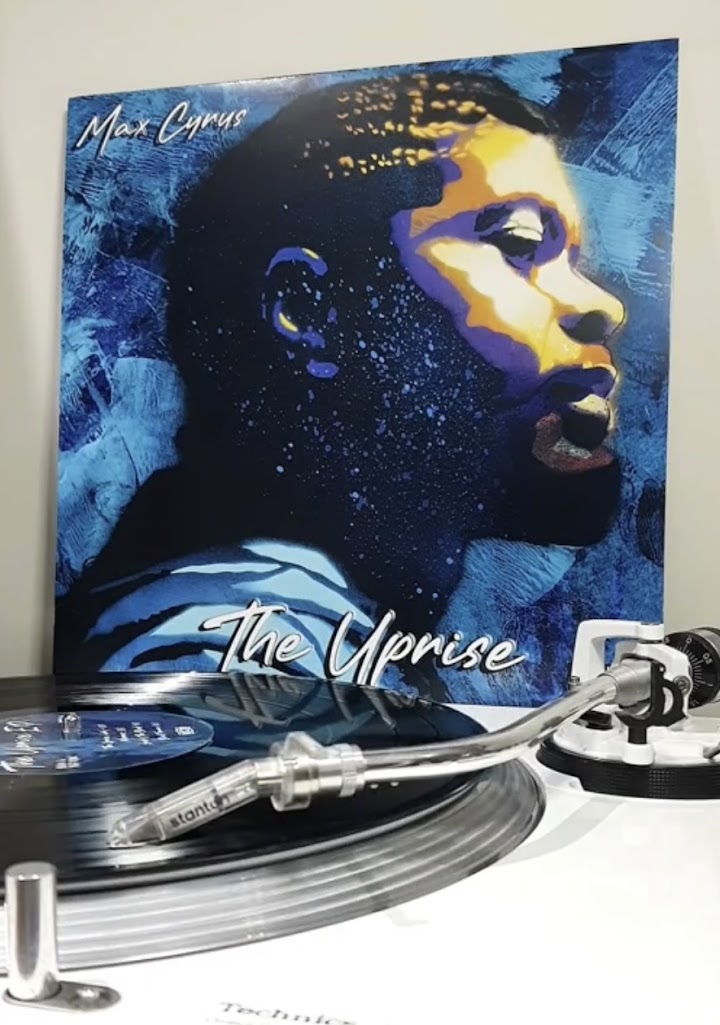

The Most Exciting Vinyl Products in The UK

ECOVIN and a huge range of colours and bespoke products from runs starting at 100. WHAT WILL YOU CREATE?

Our Services

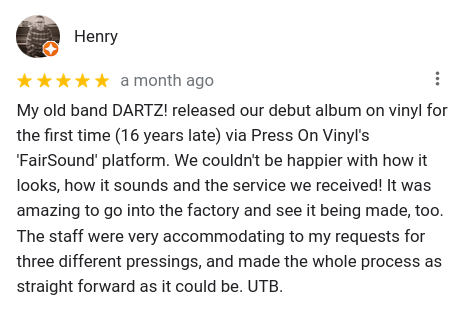

Vinyl Pressing

Our premium UK vinyl pressing service. Offering 12″ vinyl records 140g or 180g, in a wide range of opaque and translucent colours.

Special effects like marble, splatter, colour in colour, starburst and our new industry first eco vinyl!

Short runs starting from 100 available.

Fast lead times and highest quality.

Vinyl Mastering

We are happy to be partnered with Swift Mastering who bring over 20 years experience in digital and vinyl mastering at the highest level all under our roof.

This facility means we can treat every project with highest level of detail from the moment we receive the files.

Free Re-Pressing

Want to press your next release with no upfront costs?

Check our FairSound platform to find ways we can help you fund your release through a pre-order campaign and leave the manufacturing and fulfilment to us.

Already pressed with us? Bring your stampers back to life with our FREE re-pressing service.

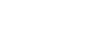

Our Unique Eco-friendly Vinyl!

Through a process of collaborative research and development our friends at INEOS have developed a world first vinyl record compound with a reduction in carbon footprint of over 90% when compared to standard Black compound.

There is no compromise in audio or visual qualities and the site which manufactures ECOVIN is within 20 miles of the plant adding to the sustainability of the product; along with our use of sustainable inks for printing, and carbon offset on steam production.

Eco-Friendly Vinyl is becoming increasingly popular with artists and customers and we are passionate about improving our sustainability with the aim of eventually becoming a net zero production facility.

Get Your Vinyl Quote Instantly

With full access to all of our our vinyl products, you can price your next vinyl run with our configurator and choose the run that best suits your needs.

How it Works

Step One / Mastering & Cutting

At Press On Vinyl we understand how important the audio quality of your record is to you and your fans.

We can help guide you through the process to ensure your audio files are ready to hit the lathe (see our FAQ). If you would like us to handle the audio mastering for you, then our team of highly experienced engineers will make sure your music works perfectly on the vinyl format.

We perform all our master cuts using the time-proven, best methods on quality lacquer discs. Our highly skilled engineers will ensure your master disc is cut perfectly through our high end analogue chain and cutting lathe.

Step Two / Metalwork

From your master lacquer discs we will produce a quality set of stampers that are accurately formed for our pressing machines.

Our high spec stamper laboratory has the latest cutting-edge technology ensuring the highest standards of quality control at every stage of the process.

Step Three / Press On

We searched the industry for the best solution for the pressing process.

Our revolutionary new machines produce consistent quality records with lower energy consumption. Powered by a bespoke steam and cooling system, the whole operation is designed to deliver the best precision manufacturing in the industry.

Our pressing operators have pride in every record they press and take time to perform quality checks at every stage.

However creative you want to be with your disc design, our team will find a solution to press your vinyl how you want.

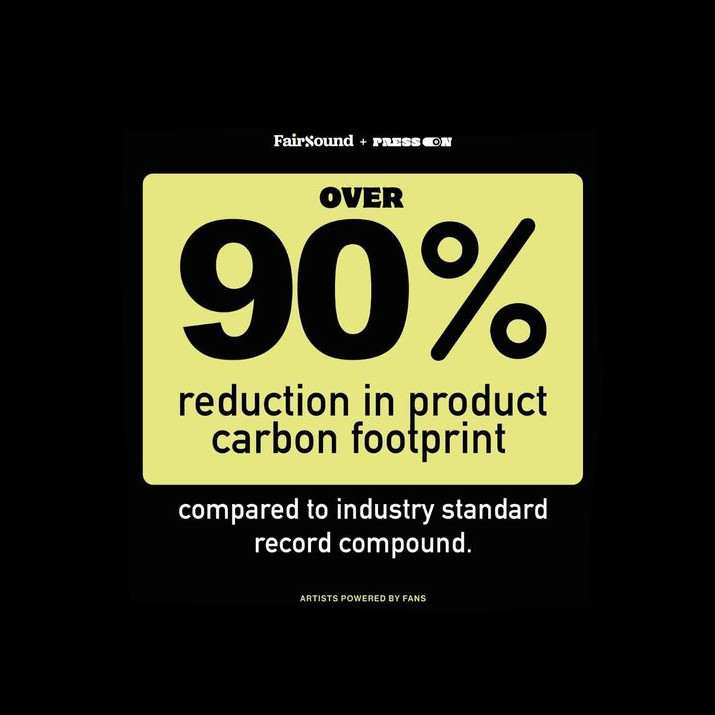

Press On Google Reviews

Read more reviews or leave us one here

Drop us a line using the contact form below and a member of the crew will be in touch.

Subscribe to our newsletter to receive special offers & discounts!

*Your details will not be shared with anyone

Build Your Vinyl Pack

Single Disc

Double Disc

Triple Disc

Colour Split

Info & Templates

FAQ

About Us

Artwork Templates

Address

Press On Vinyl Ltd

6 Ferrous Road

Middlesbrough

TS2 1DJ

Contact Us

01642 265295

sales@pressonvinyl.com

pressonvinyl.com